Machines for manufacturing spiral fabrics: Spiral winders, assembly and stuffing tables for further processing

At first LEO only built machinery for the own seam connector production. The transition to becoming a machine builder for spiral fabric manufacturers was initiated by customer requests. Taking such a major business step upon customer request establishes a very close working relationship. Still today we strive to establish and maintain such customer relationships.

From the very beginning on the objective was to build top quality machines with highest durability to match the newest standards in technology. This thinking is rooted in the conviction that the quality of the machine will have a significant effect on the quality of the final product. A problem free spiral fabric can only be assembled properly if all construction elements are made to very close tolerances. Only perfect spirals assembled flawlessly will yield problem free heat set spiral fabrics. Therefore, perfection in spirals and their assembly yields perfection and efficiency in the final product.

Today LEO Feinwerktechnik offers a wide variety of machinery for the different process steps in the production of spiral fabrics.

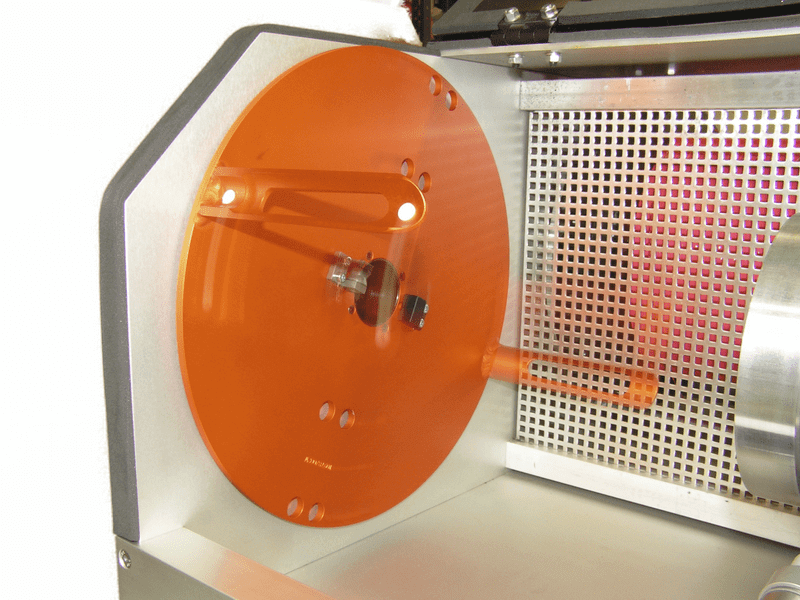

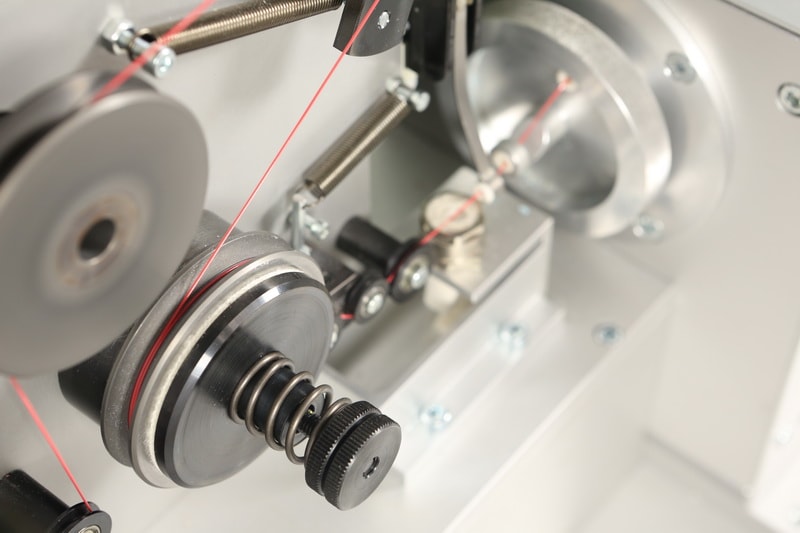

Winders

The spiral coil is the very foundation in the production of spiral fabrics. LEO offers a range of spiral winders with different production characteristics, starting with an “economy”-version continuing up to the highly productive and versatile “premium”-machine.

Assembly Table

For the further processing of the spirals LEO Feinwerktechnik offers assembly tables with different levels of automation. These assembly tables are available for working widths of 3m up to 12m. Upon customer request even higher working widths and other individualizations are possible. LEO’s top-of-the-range model is able to produce up to 30m² of spiral fabric per hour.

Stuffing Table

In order to adjust the permeability of spiral fabrics, the openings can be filled with stuffers. For spiral fabric stuffing LEO again offers a number of machines. Just like the assembly tables, the stuffing tables differ in the degree of automation and in the maximum width of the spiral fabric that can be handled.

Combination Assembly/Stuffing Table

LEO even offers the combination of assembling and stuffing in tandem on the same framework. When looking at the whole production process of spiral fabrics, these two process-steps are very logical to be combined, because this combination offers the greatest potential to improve productivity that is technically possible while generating the least amount of scrap material. Besides combining two important steps in the production of spiral fabrics, this machine also saves interim steps in the production process, like storing the assembled fabric until it can be stuffed or rewinding the raw fabric onto different tubes.

To gain insight with our spiral fabric producing machines please take a look at our product catalogue and at the videos (see video-page). We are looking forward to discussing any questions with you and to designing a spiral production program selecting a combination of machines best-suited for your needs! Individualized equipment refinements are possible upon request.